When it comes to high-performance materials for demanding industrial applications,309 stainless steel plate stands out for its excellent strength, corrosion resistance, and versatility. Known for its exceptional ability to withstand high temperatures and harsh environments, 309 stainless steel plate is widely used in industries ranging from aerospace and automotive to construction and manufacturing. In this comprehensive guide, Zhonggongte Metallurgical will explore the chemical composition and benefits of 309 stainless steel plate, and why it is considered a preferred choice in a wide range of industries.

What is 309 Stainless Steel Plate?

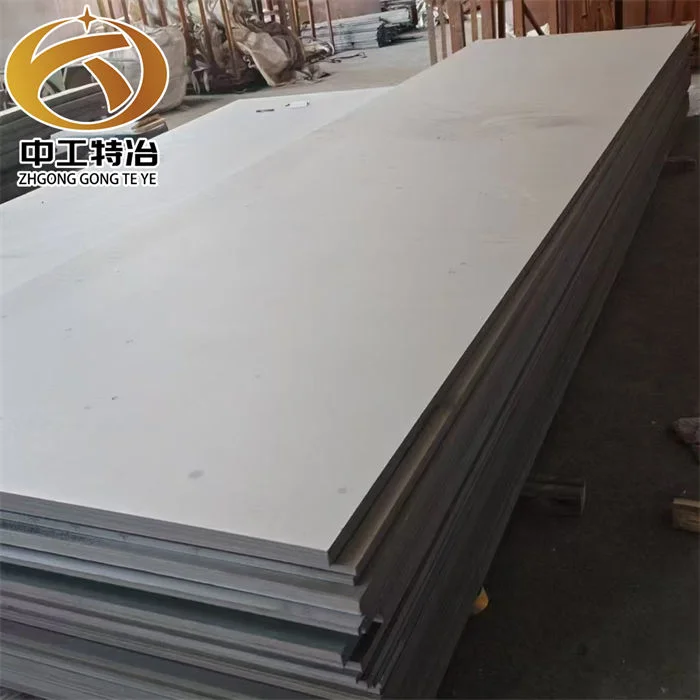

A309 stainless steel plate is a type of austenitic stainless steel known for its high chromium and nickel content. This unique composition provides superior resistance to oxidation, high-temperature environments, and various chemicals. It is commonly used in applications that require both high strength and resistance to heat, such as in the manufacturing of equipment exposed to elevated temperatures.

The 309 stainless steel plate is part of the 300 series of stainless steels, which are alloyed with chromium and nickel to offer improved resistance to corrosion and oxidation compared to other types of steel. It is particularly favored for its performance in environments that experience temperatures exceeding 1,000°F (537°C) and where standard steel would quickly degrade.

Chemical Composition of 309 Stainless Steel Plate

The primary elements in 309 stainless steel plate include:

-

Chromium (Cr): 22-24%

-

Nickel (Ni): 12-15%

-

Manganese (Mn): 2.0-3.0%

-

Silicon (Si): 1.0%

-

Carbon (C): 0.20% max

-

Phosphorus (P): 0.045% max

-

Sulfur (S): 0.030% max

This combination of elements gives 309 stainless steel plate its exceptional resistance to oxidation and heat, making it ideal for high-temperature applications. The high nickel content improves the material’s toughness and resistance to corrosion, while the chromium content provides increased resistance to oxidizing acids and high-temperature environments.

Advantages of Using 309 Stainless Steel Plate

1. Long-Term Cost Savings

Although a 309 stainless steel plate may require a higher upfront investment compared to other materials, its exceptional durability, heat resistance, and corrosion resistance make it an economical choice over the long term. This alloy is designed to withstand extreme conditions without significant degradation, reducing the frequency of repairs or replacements. In industrial settings, downtime caused by component failure can be costly—not only in terms of repair expenses but also lost productivity. By choosing a 309 stainless steel plate, companies benefit from reduced maintenance requirements, minimal material degradation, and a much longer service life. These advantages translate into substantial cost savings throughout the lifespan of the equipment.

2. Improved Performance

The 309 stainless steel plate is engineered to perform reliably under demanding operational conditions. It maintains its mechanical strength and structural integrity even when exposed to high temperatures, making it ideal for furnace components, heat exchangers, and other thermal processing equipment. In environments involving corrosive chemicals or fluctuating thermal cycles, the 309 stainless steel plate resists oxidation and scaling, ensuring consistent performance. This reliability reduces the likelihood of unexpected breakdowns, keeping operations running smoothly and efficiently. As a result, industries benefit from better equipment uptime and enhanced overall productivity.

3. Versatility

One of the defining advantages of a 309 stainless steel plate is its adaptability to diverse industrial applications. It offers a combination of high-temperature tolerance, corrosion resistance, and mechanical strength, which makes it suitable for industries as varied as petrochemical, aerospace, power generation, and food processing. For example, in the aerospace industry, the 309 stainless steel plate is used for components exposed to intense heat, while in the food processing sector, it serves in environments where hygiene and corrosion resistance are critical. This wide-ranging applicability ensures that businesses can rely on a single, high-performance material for multiple operational needs.

In conclusion,309 stainless steel plate is an outstanding material that offers exceptional properties for high-temperature and corrosion-resistant applications. With its superior strength, durability, and versatility, it is an indispensable material in industries where reliability and performance are essential. Whether for use in furnaces, chemical processing equipment, or exhaust systems,309 stainless steel plate provides a solution that stands the test of time, ensuring that your systems operate smoothly and efficiently in the most demanding environments.

www.zhonggongtemetal.com

Jiangsu Zhonggongte Metallurgical Technology Co., Ltd.