In the world of molded foam manufacturing, the efficiency and precision of polyurethane (PU) mixing systems play a critical role in product quality and operational productivity. Among the essential components of these systems are low pressure mix-heads—specialized devices designed to blend polyurethane components with high accuracy and consistency.

As the demand for lightweight, durable, and comfortable foam products continues to grow across various industries, understanding the applications of low pressure mix-heads becomes increasingly important. With years of industry expertise, Haifeng, a leading manufacturer of polyurethane production and processing equipment, has been at the forefront of mix-head innovation, helping manufacturers meet the evolving demands of the global market.

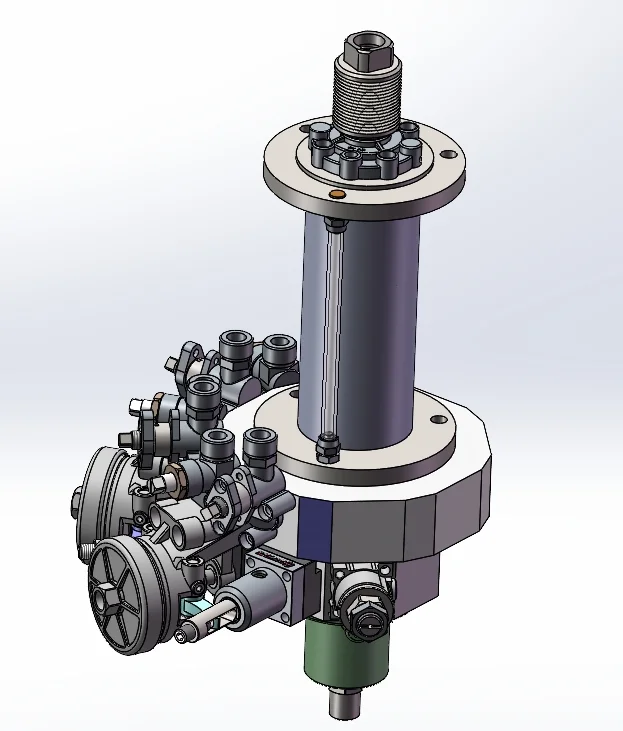

What Is a Low Pressure Mix-Head?

A low pressure mix-head is a critical element of polyurethane foaming equipment. It ensures the homogeneous mixing of polyol and isocyanate—the two base chemicals used in PU foam production—by blending them at relatively low pressure (typically under 25 bar) using mechanical stirrers rather than high-velocity impingement.

These mix-heads are most commonly integrated into low-pressure foaming machines used for the production of molded foam parts, where accuracy, consistency, and ease of maintenance are key.

Key Applications in Molded Foam Manufacturing

1. Automotive Interiors and Seating

Automotive manufacturers rely on molded polyurethane foam for car seats, headrests, armrests, and insulation components. Low pressure mix-heads are ideal for producing these parts due to their precise dosing capabilities and reliable mixing quality.

Haifeng’s mix-head systems support consistent cell structure and density in automotive foam parts, ensuring optimal comfort, durability, and performance under varying environmental conditions.

2. Furniture and Bedding

In the furniture and mattress industry, comfort and resilience are everything. Low pressure mix-heads facilitate the accurate blending of additives and polyol blends to achieve specific softness, rebound, and durability characteristics.

Haifeng’s technology enables manufacturers to produce a wide range of PU foam grades with consistent quality, essential for mass production of high-end mattresses, cushions, and ergonomic furniture.

3. Footwear and Insoles

Molded foam insoles and shoe components benefit greatly from the fine control offered by low pressure mix-heads. These applications require uniform density, quick cycle times, and the ability to incorporate dyes or additives.

Haifeng offers customizable mix-head configurations that allow manufacturers to easily adapt to diverse formulations and designs, ensuring flexibility without sacrificing quality.

4. Medical and Ergonomic Products

The production of molded foam used in orthotics, wheelchair cushions, and medical support devices demands high precision and reliability. Low pressure mix-heads excel in delivering exact dosing and uniformity, which are crucial in applications where user comfort and safety are paramount.

Haifeng’s equipment meets the stringent standards required in healthcare applications, offering clean mixing technology and easy-to-clean designs that minimize cross-contamination.

5. Custom Foam Parts and Prototyping

For R&D departments and prototyping facilities, low pressure mix-heads offer unparalleled flexibility. Their ability to switch between formulations with minimal downtime makes them ideal for testing new products or small-batch runs.

Haifeng’s advanced systems allow for modular upgrades, data tracking, and integration with digital process monitoring tools—making them perfect for agile manufacturing environments.

Advantages of Haifeng’s Low Pressure Mix-Heads

Superior Mixing Accuracy: Ensures uniform cell structure and minimizes waste.

Energy Efficiency: Operates at lower pressures, reducing energy consumption and operational costs.

User-Friendly Maintenance: Modular design allows for easy cleaning and part replacement.

Smart Integration: Compatible with automated PU production lines and Industry 4.0 standards.

Tailored Solutions: Customizable to fit specific production needs, from footwear to automotive interiors.

Conclusion

Low pressure mix-heads are a cornerstone of modern molded foam manufacturing, offering versatility, precision, and control across multiple industries. Their ability to deliver consistent quality while reducing operational complexity makes them a smart investment for any foam production facility.

As an industry leader, Haifeng continues to drive innovation in polyurethane processing with its advanced line of low pressure mix-heads and fully integrated production systems. Whether you're producing high-end automotive seating or custom orthopedic supports, Haifeng provides the technology and expertise needed to bring your foam products to life with efficiency and precision.

Discover Haifeng’s full range of polyurethane equipment solutions and take your foam manufacturing to the next level.

Top 5 Features of Low Pressure Mix-heads and Why They Matter in PU Processing

www.haifeng-automation.cn

Haifeng