In the rapidly growing era of renewable energy, electric mobility and storage systems, lithium-ion battery facilities have become critical infrastructure. At the same time, they represent one of the most challenging fire-safety hazards of our age. Recent incidents highlight that traditional fire prevention strategies may no longer suffice. By deploying advanced monitoring technologies such as distributed optical fiber sensing systems, operators can dramatically improve the early detection and control of thermal anomalies, and thereby reduce the risk of catastrophic events.

The Rising Risk of Lithium-Battery Storage Fires

Lithium-ion batteries are favoured for their high energy density and rapid charge/discharge capability, but they also carry inherent safety risks. A phenomenon known as “thermal runaway” may be triggered by internal cell defects, external heating, mechanical damage or manufacturing faults.

For example, in June 2024 a large manufacturing facility in South Korea experienced a fatal fire after a battery warehouse housed over 35,000 lithium cells caught fire and exploded. In another location, a battery-storage facility in the United States was the scene of an evacuation after a fire at a large-scale installation, underscoring the industry-wide nature of the challenge.

Warehouse environments amplify risk because of high-density shelving, large volumes of stored cells, layered racks, and compressed fire-suppression constraints. A recent technical study of a lithium-battery warehouse examined seven layers of shelving separated by fire-proof panels, yet still required extensive monitoring to detect abnormal heat build-up.

Why Conventional Fire Protection May Fall Short

Traditional fire detection systems—smoke detectors, heat sensors, sprinklers—were designed for “classic” materials and fire progressions. But lithium-ion fires behave differently: they can ignite within a cell in seconds, propagate rapidly, generate highly toxic gases, and produce temperatures that overwhelm traditional suppression systems.

In many cases, by the time smoke is detected, the fire is already well established. Furthermore, in densely packed battery warehouses, access for firefighting may be restricted, racks may collapse, and toxic emissions may hinder personnel. All of this elevates the need for early, continuous and distributed sensing of conditions such as temperature, stress, and vibration.

Introducing Distributed Optical Fiber Sensing

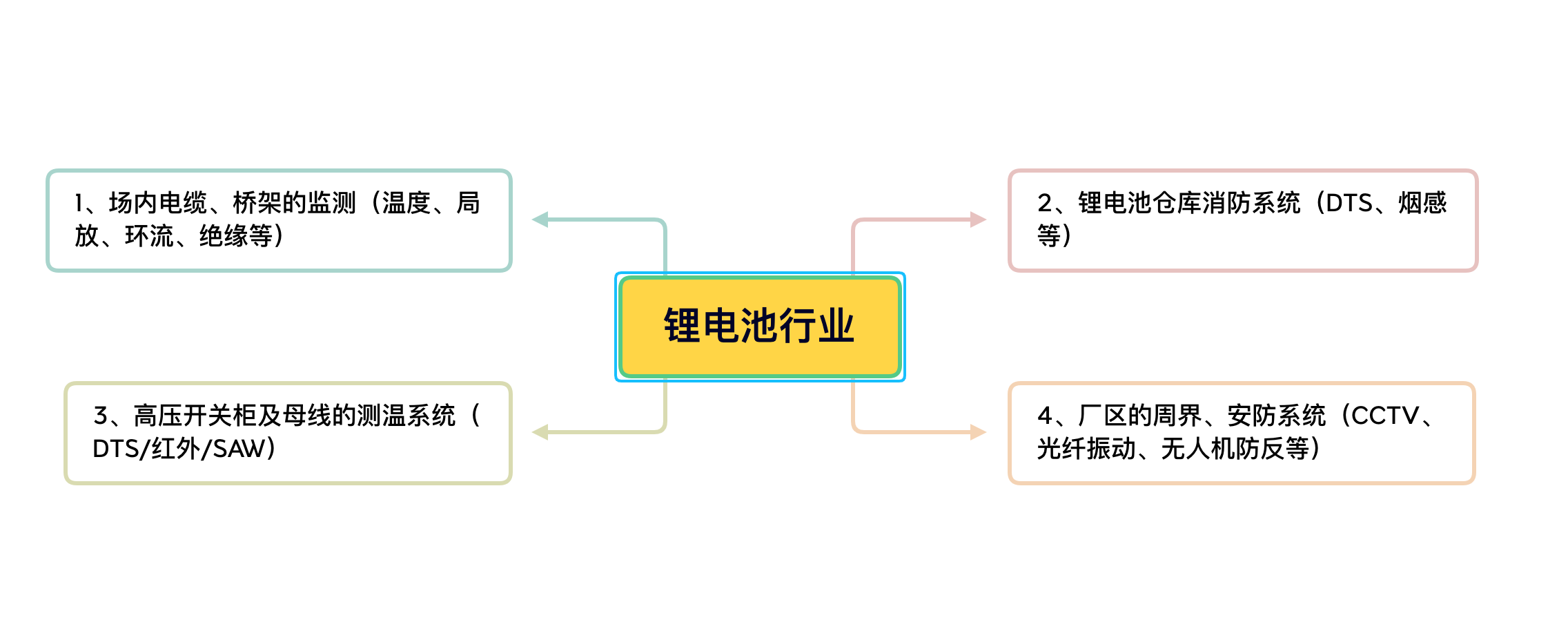

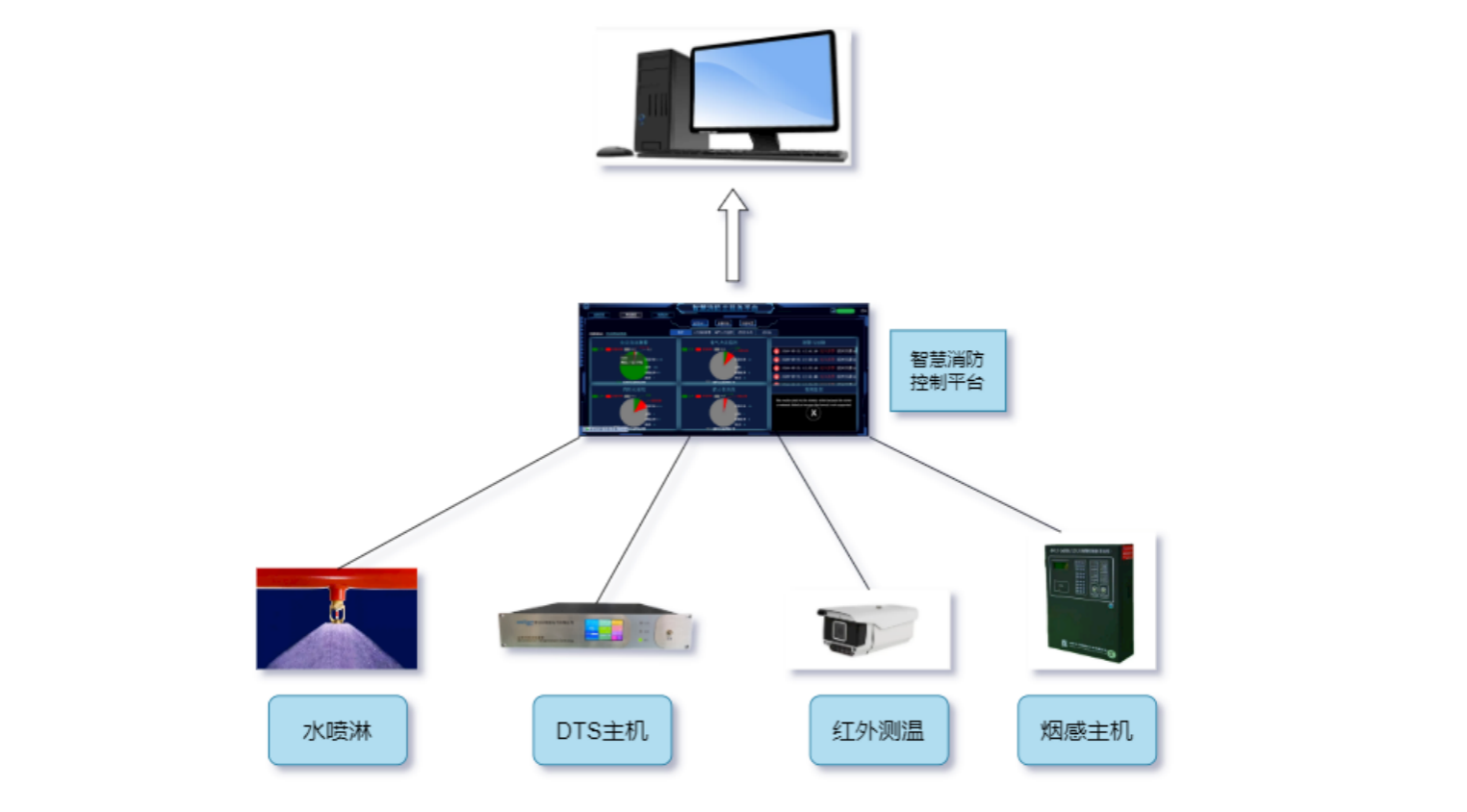

This is where technologies like distributed optical fiber sensing step in. In particular, the solution offered by Shenzhen Mingsheng Electrical Co., Ltd. (MINSAINT) through its Distributed Optical Fiber Sensing product line provides a paradigm shift in monitoring.

Unlike spot sensors that monitor only one point, a distributed optical fiber sensor allows for continuous, real-time monitoring along the entire length of an optical cable. It can detect anomalies in temperature, strain or acoustic vibration over hundreds or even thousands of metres. Because the optical fibre itself acts as the sensor medium, installations are compact, intrinsically safe (non-electrical at the sensing point), and able to cover large areas with high resolution.

How It Works

The core principle is based on fibre-optic sensing techniques such as DTS (Distributed Temperature Sensing). These systems send laser pulses into optical fibres; by analysing back-scattered light (e.g., Raman scattering) the system derives temperature events along the fibre.

If a lithium-battery rack begins to overheat, the distributed fibre will detect the temperature rise and send an alert. If mechanical stress or rack movement occurs (potential indicator of collapse or fault propagation), a strain sensor can detect it. Acoustic sensors can pick up subtle cracking or gassing events before they manifest visibly.

For example, a shelving module in a warehouse could have an optical cable routed around the perimeter of each racking zone, looped through panels, and connected to a central analyser. Once a threshold is crossed, the system triggers a local alarm and links to facility management systems for automated response.

Application in Battery Warehouses

In practical terms, deploying a system like MINSAINT’s enables warehouse operators to:

-

Monitor temperature gradients across shelving levels, thereby identifying hotspots long before visible signs appear.

-

Detect in-rack stress or deformation, which might indicate structural compromise or creeping thermal expansion.

-

Integrate with fire-safety workflows so that an early anomaly triggers immediate inspections, cooldown procedures or evacuation if needed.

-

Replace or augment traditional sensor arrays with distributed cables that cover much larger physical footprints, reducing installation complexity and maintenance overhead.

Consider a scenario: a pallet in the upper shelving tier begins to self-heat due to an internal defect. The distributed fibre cable detects a rising temperature before the cell vents or ignites. The system sends an alert to the facility control room. Staff isolate the zone, initiate an inert-gas purge, and remove the pallet before the event escalates. Without that early detection, the situation might quickly escalate into full thermal runaway, destructive fire and possible explosion.

Case Study Insights

Studies show that warehouse layout, shelf spacing and state of charge of lithium-ion storage all influence fire risk. 科学直接 Meanwhile, logistics firms have reported that many 3PL facilities lack proper advanced detection systems and fire-sprinkler upgrade paths for battery storage. ALOM In one deployment, optical fibers were routed around seven shelving layers and segmented into multiple alarm zones—each zone capable of independent detection and alerting. AP Sensing GmbH

By combining these findings with distributed optical fiber sensing solutions, operators gain a critical advantage: early detection, continual monitoring, and actionable intelligence.

Integrating Sensing into a Holistic Safety Strategy

Implementing an optical fiber sensing system by itself is not a silver-bullet—but it is a major enhancement to a comprehensive risk-mitigation strategy. Key complementary measures include:

-

Proper warehouse design: using fire-resistant materials, adequate rack spacing, ventilation and containment zones.

-

Monitoring of battery state-of-charge, ambient conditions, thermal runaway triggers (such as over-temperature or mechanical shock).

-

Integration with fire-suppression systems: e.g., inert-gas flooding, advanced sprinkler design, compartmentalization.

-

Continuous safety training for staff, emergency drills, and oversight from fire-certified professionals.

When distributed optical fiber sensing is integrated into this framework, it supports the proactive identification of abnormal conditions rather than simply reacting to smoke or flames.

Why Manufacturers and Facility Operators Should Care

For manufacturers, suppliers and industrial facility operators, investing in next-generation monitoring systems brings real benefits:

-

Reduced risk of catastrophic loss: a warehouse fire can not only destroy inventory but also generate toxic plumes, trigger evacuations and invite heavy regulatory scrutiny.

-

Real-time data, less downtime: early alerts mean less business interruption, less damage, fewer insurance claims.

-

Compliance and competitiveness: As regulatory frameworks for high-density battery storage tighten globally, being ahead of the curve gives a strategic advantage.

-

Customisation and scalability: Systems like those offered by MINSAINT are designed for industrial scale, customised for new energy, battery storage, tunnels, pipelines and other infrastructure.

The MINSAINT Advantage

MINSAINT leverages high-tech talent in China’s opto-electronic sensing field, designing and developing distributed fiber-optic systems in house. Their solutions cover a wide range—temperature, acoustic, strain, integrated communications—and are deployed in sectors including power, petrochemical, new energy, tunnels, oil-gas pipelines and storage tanks. Through this depth of industrial application, their systems have been proven, recognised and trusted by customers across critical infrastructure sectors.

For facility operators with lithium-ion battery warehouses, integrating MINSAINT’s distributed optical fiber sensing systems offers a strategic step forward: continuous visibility, early anomaly detection, and peace of mind in a high-risk environment.

Final Thoughts

Lithium-battery warehouse fires are no longer rare. With thousands of tonnes of stored cells, high shelving, tight spacing, and inherently volatile chemistry, the potential for rapid escalation is real. Traditional detection systems may alert too late. By contrast, distributed optical fiber sensing provides facility owners with early-warning capability, scalable coverage, and actionable intelligence.

If you are responsible for battery-storage facilities, electric-mobility logistics or large-scale energy storage systems, it’s time to rethink your monitoring architecture. Explore how you can deploy distributed fiber-optic sensing systems with advanced temperature, strain and acoustic monitoring—and build a safer, more resilient infrastructure.

Click through to learn more about MINSAINT’s solutions here: Distributed Optical Fiber Sensing.

www.minsaint.com

Shenzhen Mingsheng Electrical Co ., Ltd. ( MINSAINT)