In the intricate world of engineering, the concept of joints plays a pivotal role in the assembly and functionality of structures. The versatility of engineering joints is vast, catering to the diverse needs of various industries. In this article, we will delve deep into the question: How many types of engineering joints are there? By exploring the intricacies of different joint types, we aim to provide valuable insights for engineers and enthusiasts alike.

I. Basic Classification of Engineering Joints:

A. Temporary Joints:

1. Snap Fit Joints

2. Screw Joints

3. Riveted Joints

B. Permanent Joints:

1. Welded Joints

2. Adhesive Joints

3. Brazed Joints

II. Mechanical Joints:

A. Kinematic Joints:

1. Sliding Joints

2. Revolute Joints

3. Cylindrical Joints

B. Non-Kinematic Joints:

1. Rigid Joints

2. Flexible Joints

3. Spherical Joints

III. Structural Joints:

A. Tension Joints

1. Lap Joints

2. Butt Joints

B. Compression Joints:

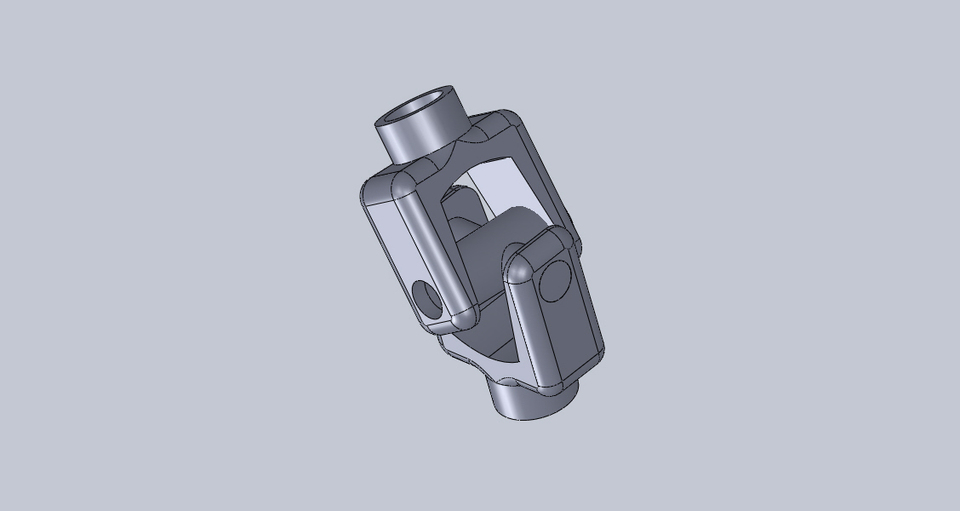

1. Clevis Joints

2. Knuckle Joints

IV. Advanced Engineering Joints:

A. Shape Memory Alloy Joints

B. Magnetic Joints

C. Composite Joints

V. Applications and Considerations:

A. Aerospace Industry

B. Automotive Engineering

C. Civil Engineering

D. Biomedical Engineering

Conclusion:

In conclusion, the world of engineering joints is remarkably diverse, with each type serving specific purposes across various industries. Engineers must carefully consider the type of joint suitable for their applications, taking into account factors like strength, flexibility, and durability. This comprehensive guide serves as a valuable resource for anyone seeking a deeper understanding of the multitude of engineering joints available.