Read Time:6 Minute, 50 Second

Rising Significance of Precision Gear Processing in Wind Power

In the era of global climate change and the urgent need for sustainable energy solutions, wind power has emerged as a crucial player in the renewable energy sector. As countries around the world strive to achieve their "carbon peak" and "carbon neutrality" goals, the wind power industry is experiencing rapid growth and scaling up at an unprecedented pace. In China alone, the installed capacity of wind power has been increasing dramatically, with significant contributions from both onshore and offshore wind farms.

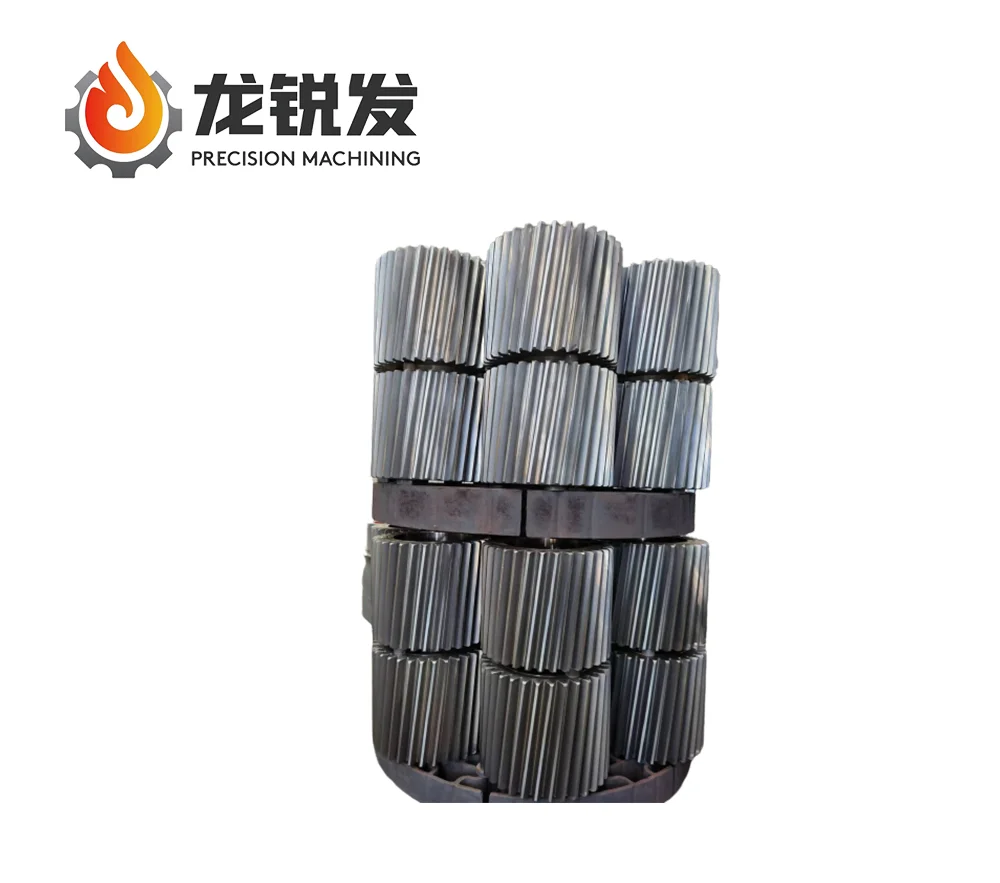

At the heart of every wind turbine lies a complex system of gears and gearboxes, which play a vital role in converting the kinetic energy of the wind into electrical power. These components are subject to harsh operating conditions, including high speeds, heavy loads, and varying environmental factors. Therefore, the precision and reliability of wind power gears and gearboxes are of paramount importance. Any failure or inefficiency in these components can lead to significant downtime and maintenance costs, thereby affecting the overall efficiency and profitability of wind power projects. In this blog post, as a high quality industrial gear manufacturing factory, Longruifa will share the significance of precision wind power gear processing.

Intricacies of Wind Power Gear Processing

Wind power gear processing is a highly specialized field that requires meticulous attention to detail and advanced manufacturing techniques. The process involves multiple stages, each with its own set of challenges and requirements. From the initial design and material selection to the final inspection and testing, every step must be carefully executed to ensure the highest quality and performance of the gears.

One of the key aspects of wind power gear processing is the use of precision cutting tools and machines. These tools must be capable of achieving extremely tight tolerances and surface finishes, as even minor deviations can lead to significant losses in efficiency and durability. Advanced techniques such as gear grinding and honing are often employed to refine the gear teeth and improve their overall performance.

Another critical factor in wind power gear processing is the heat treatment process. This involves subjecting the gears to high temperatures to alter their microstructure and improve their mechanical properties, such as hardness and toughness. Proper heat treatment is essential for ensuring the gears can withstand the high stresses and loads encountered during operation. However, this process must be carefully controlled to avoid defects and deformations that could compromise the gear's performance.

Role of Metalworking Fluids in Precision Gear Processing

Metalworking fluids play a vital role in the precision gear processing industry. These fluids serve multiple functions, including cooling, lubricating, and cleaning the cutting tools and workpieces during the machining process. The choice of the right metalworking fluid can significantly impact the efficiency, quality, and longevity of the gears being produced.

For wind power gear processing, the requirements for metalworking fluids are particularly stringent. The fluids must be able to withstand the high temperatures and pressures generated during cutting operations, while also providing excellent lubrication to reduce friction and wear. Additionally, they must be environmentally friendly and compatible with the materials and coatings used in the gears.

There are several types of metalworking fluids commonly used in wind power gear processing, including cutting oils, heat treatment oils, and rust preventive oils. Each type of fluid is formulated to meet the specific demands of its application, ensuring optimal performance and protection of the gears throughout the manufacturing process.

Cutting Oils: Enhancing Precision and Tool Life

Cutting oils are essential in the precision gear processing of wind power components. These oils are specifically designed to provide superior lubrication and cooling during cutting operations, such as milling, turning, and grinding. By reducing friction and heat generation, cutting oils help to maintain the sharpness and longevity of cutting tools, thereby improving the overall efficiency and quality of the machining process.

In wind power gear processing, cutting oils must be capable of handling the high loads and complex geometries associated with gear manufacturing. They must also be formulated to provide excellent surface finish and dimensional accuracy, ensuring that the gears meet the stringent requirements of the wind power industry. Advanced cutting oils often incorporate specialized additives, such as extreme pressure (EP) agents and anti-wear additives, to enhance their performance and protect both the tools and the workpieces.

Heat Treatment Oils: Ensuring Gear Durability

Heat treatment is a critical process in wind power gear manufacturing, as it significantly enhances the mechanical properties of the gears. During heat treatment, gears are subjected to high temperatures to achieve desired hardness, strength, and toughness. However, this process can also introduce stresses and deformations if not properly controlled.

Heat treatment oils play a crucial role in managing the heat treatment process. These oils are designed to provide uniform cooling rates, ensuring that the gears achieve the desired properties without developing defects or deformations. Proper selection of heat treatment oils is essential for optimizing the performance and durability of wind power gears.

Heat treatment oils must possess excellent thermal stability and oxidation resistance to withstand the high temperatures encountered during the process. They must also be formulated to minimize quenching stresses and prevent cracking or distortion of the gears. Additionally, heat treatment oils should be easy to apply and remove, ensuring a smooth and efficient manufacturing process.

Rust Preventive Oils: Protecting Gears from Corrosion

Rust preventive oils are another essential component in the wind power gear processing arsenal. These oils are designed to protect gears from corrosion during storage, transportation, and between manufacturing processes. Corrosion can significantly degrade the performance and lifespan of gears, making rust prevention a critical aspect of wind power gear manufacturing.

Rust preventive oils form a protective barrier on the surface of the gears, preventing moisture and other corrosive agents from coming into contact with the metal. These oils are typically formulated with specialized corrosion inhibitors and antioxidants to provide long-lasting protection. They must also be compatible with other manufacturing processes and materials, ensuring that they do not interfere with subsequent operations such as assembly or coating application.

Future of Precision Wind Power Gear Processing

As the wind power industry continues to grow and evolve, the demand for precision gear processing will only increase. Manufacturers are constantly seeking new and innovative ways to improve the efficiency, reliability, and sustainability of their gear manufacturing processes. This includes the development of advanced materials, cutting-edge manufacturing technologies, and more environmentally friendly metalworking fluids.

One of the emerging trends in precision wind power gear processing is the integration of digital technologies and Industry 4.0 principles. This involves the use of advanced sensors, data analytics, and automation to optimize the manufacturing process in real-time. By leveraging these technologies, manufacturers can achieve higher levels of precision and consistency, while also reducing waste and improving overall efficiency.

Another important area of development is the focus on sustainability. The wind power industry is committed to reducing its environmental impact, and this extends to the manufacturing processes as well. Manufacturers are increasingly looking for ways to minimize energy consumption, reduce waste, and use more eco-friendly materials and fluids in their operations. This includes the development of bio-based and water-soluble metalworking fluids, as well as the adoption of more sustainable manufacturing practices.

Conclusion

Precision wind power gear processing is a complex and critical field that plays a vital role in the success of the wind power industry. The high demands placed on wind power gears and gearboxes require manufacturers to employ advanced manufacturing techniques, high-quality materials, and specialized metalworking fluids to ensure the highest levels of precision and reliability. As the industry continues to grow and evolve, the importance of precision gear processing will only increase, driving further innovation and development in this crucial area.

By staying at the forefront of technological advancements and adopting sustainable practices, manufacturers can meet the challenges of precision wind power gear processing and contribute to the ongoing growth and success of the wind power industry. The future of wind power depends on the continuous improvement and innovation in gear manufacturing, ensuring that this vital renewable energy source remains a reliable and efficient solution for meeting the world's energy needs.

www.lrfgears.com

Longruifa