Mechanical damage is a pervasive issue across various industries, encompassing a wide range of detrimental effects on equipment, structures, and materials. Understanding the different types of mechanical damage, their underlying causes, and effective mitigation strategies is crucial for ensuring the longevity and reliability of machinery and infrastructure. In this comprehensive blog post, we delve into the intricacies of mechanical damage, providing valuable insights for professionals across diverse fields.

- Abrasion:

Abrasion is a common type of mechanical damage characterized by the wearing away of material surfaces due to frictional forces. It occurs when two surfaces rub against each other, leading to the removal of material particles. Factors such as surface roughness, hardness, and the presence of contaminants can significantly influence the severity of abrasion. Effective measures to mitigate abrasion include the use of protective coatings, lubrication, and the selection of appropriate materials with enhanced wear resistance. - Fatigue:

Fatigue damage occurs when materials or structures undergo repeated cyclic loading, leading to progressive and localized damage. This type of damage is particularly prevalent in industries such as aerospace, automotive, and civil engineering. Factors such as stress concentration, material defects, and environmental conditions can accelerate fatigue failure. Employing techniques like stress analysis, fatigue testing, and the implementation of design modifications can help mitigate fatigue damage and enhance the structural integrity of components. - Impact:

Impact damage results from sudden and high-energy forces applied to a material or structure. It can occur due to collisions, drops, or other external forces. The severity of impact damage depends on factors such as the magnitude and duration of the force, material properties, and the presence of pre-existing defects. Mitigation strategies for impact damage include the use of impact-absorbing materials, structural reinforcements, and the implementation of proper handling and transportation protocols. - Corrosion:

Corrosion is a chemical process that leads to the degradation of materials, resulting in mechanical damage. It occurs when materials react with their surrounding environment, leading to the formation of oxides, salts, or other compounds that weaken the material's structural integrity. Understanding the different types of corrosion, such as galvanic, pitting, and crevice corrosion, is crucial for implementing effective prevention and mitigation strategies. These strategies may involve the use of protective coatings, corrosion inhibitors, and regular maintenance practices. - Erosion:

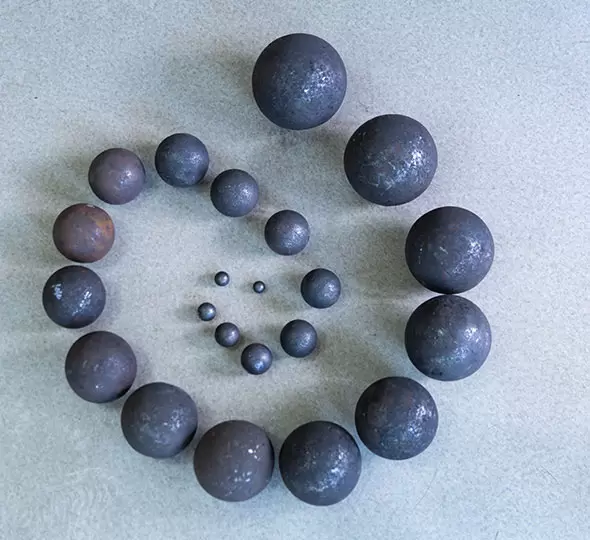

Erosion damage occurs when materials are gradually worn away by the impact of solid particles, liquids, or gases. It is commonly observed in industries such as mining, oil and gas, and hydraulic systems. Factors such as particle velocity, size, and material properties influence the severity of erosion damage. Employing erosion-resistant materials, implementing proper filtration systems, and optimizing fluid flow dynamics can help mitigate erosion damage and extend the lifespan of equipment.

Conclusion:

Mechanical damage encompasses a diverse range of detrimental effects that can significantly impact the performance and reliability of equipment and structures. By understanding the various types of mechanical damage, their underlying causes, and effective mitigation strategies, professionals across industries can proactively address these challenges. Implementing appropriate measures such as protective coatings, design modifications, and regular maintenance practices can ensure the longevity and optimal functioning of machinery and infrastructure, ultimately leading to enhanced operational efficiency and cost savings.