Spear bolts, often overlooked in the broader spectrum of fasteners, play a pivotal role in engineering applications ranging from aerospace to automotive and beyond. Their unique design and structural characteristics contribute significantly to the strength, durability, and functionality of various systems.

Structural Components of Spear Bolts

Thread Design

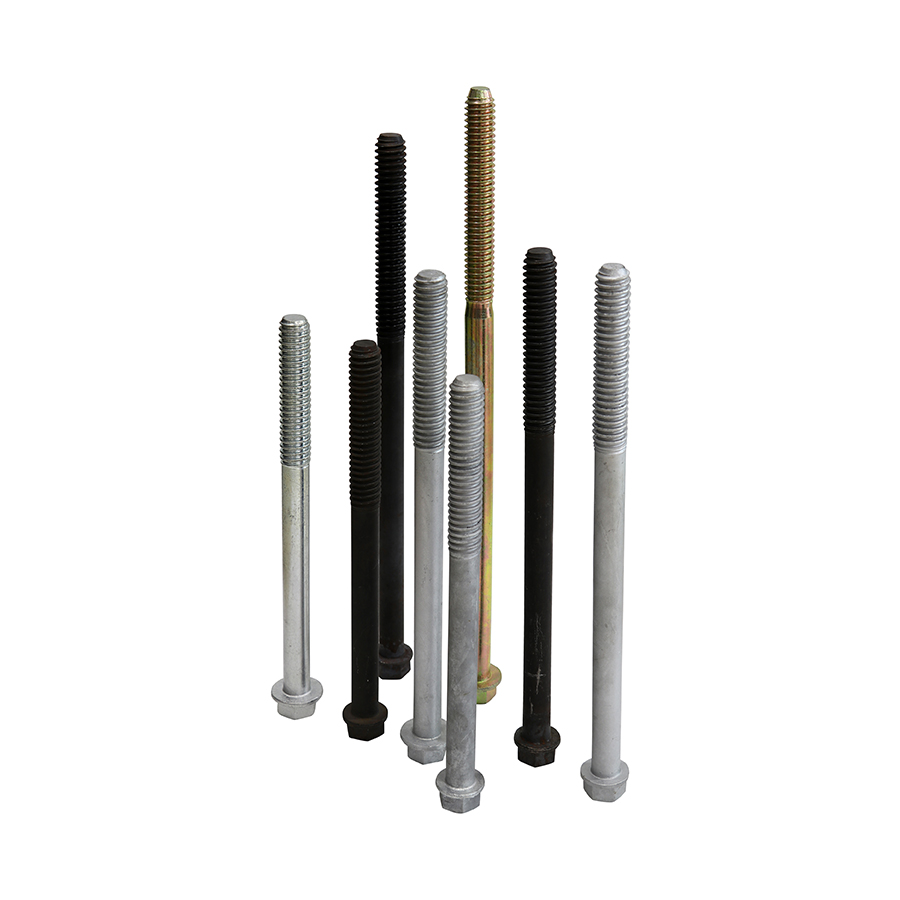

The thread of a spear bolt is not merely a spiral pattern carved into the shaft; it is a meticulously engineered feature that ensures secure clamping and load transfer. The pitch, thread angle, and thread profile all influence the bolt's tensile strength, torque requirements, and resistance to loosening. For instance, fine threads provide better resistance to vibration but require more torque to tighten, whereas coarse threads are easier to install but may be less secure under dynamic loads.

Head Configuration

The head of a spear bolt serves multiple purposes: it provides a bearing surface for tools, distributes clamping forces evenly, and prevents the bolt from being pulled through the material it fastens. Different head styles such as hex, socket, and square heads cater to specific installation needs and accessibility constraints. The underhead design, including chamfers and radiuses, further optimizes installation and reduces stress concentrations.

Shank and Tip Geometry

The shank, the main body of the bolt, must withstand tensile and shear forces while maintaining alignment. Its diameter and length are critical parameters that affect the bolt's load-bearing capacity. The tip of a spear bolt, often sharpened like a spear, facilitates easier penetration into pre-drilled holes, which is particularly advantageous in assembly processes involving soft or brittle materials.

Material Selection and Properties

Alloy Steels

Alloy steels are a popular choice for spear bolts due to their high strength-to-weight ratio, corrosion resistance, and ability to undergo heat treatment for enhanced mechanical properties. Grades like ASTM A325 and A490 are commonly used in structural applications requiring high tensile strength.

Stainless Steels

Stainless steels offer excellent corrosion resistance, making them suitable for environments exposed to moisture, chemicals, or salt. Although they typically have lower tensile strengths compared to alloy steels, grades like ASTM A193 B8 and B8M are favored in marine, food processing, and medical applications.

Titanium and Nickel Alloys

For applications demanding lightweight materials with exceptional corrosion resistance and high-temperature stability, titanium and nickel alloys are employed. These materials are costly but offer significant advantages in aerospace and nuclear engineering.

Importance in Engineering Applications

Structural Integrity

Spear bolts are crucial in maintaining the structural integrity of assemblies. Their precise design ensures that loads are distributed evenly, preventing localized failures that could compromise the entire system. In critical structures like bridges, aircraft, and pressure vessels, the reliability of spear bolts is paramount.

Assembly Efficiency

The unique tip design of spear bolts facilitates rapid and accurate assembly, reducing installation time and labor costs. This efficiency is particularly valuable in mass-production environments and in assembly lines where time is a critical factor.

Safety and Compliance

In safety-critical applications, the use of properly specified spear bolts is mandatory to comply with industry standards and regulatory requirements. Their ability to withstand extreme loads and environmental conditions ensures the reliability and longevity of the systems they secure.

Conclusion

The structural characteristics of spear bolts, from their thread design to material selection, are finely tuned to meet the diverse demands of engineering applications. Their role extends beyond mere fastening; they are integral to ensuring structural integrity, assembly efficiency, and safety compliance. As technology advances and engineering challenges become more complex, the importance of understanding and optimizing the design of spear bolts will only grow. By appreciating their nuanced attributes, engineers can harness their full potential, driving innovation and reliability across various industries.

www.hbrailwayfastening.com

Suzhou HuiBo Railway Fastener Co.,Ltd.